done call_split thumb_up photo_camera gps_fixed qr_code

CHECKWORK | MANUFACTURING

Manufacturing Inspection Software

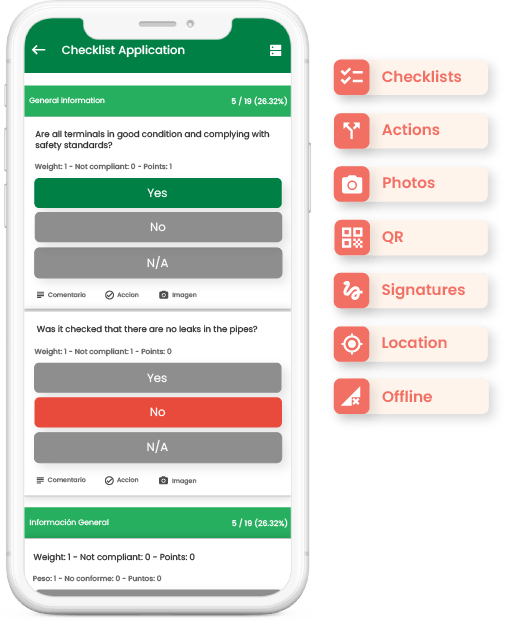

Allow your employees to work in a safe and efficient environment, maximizing the quality and performance of your production line, reducing the time to fill out old paper forms.

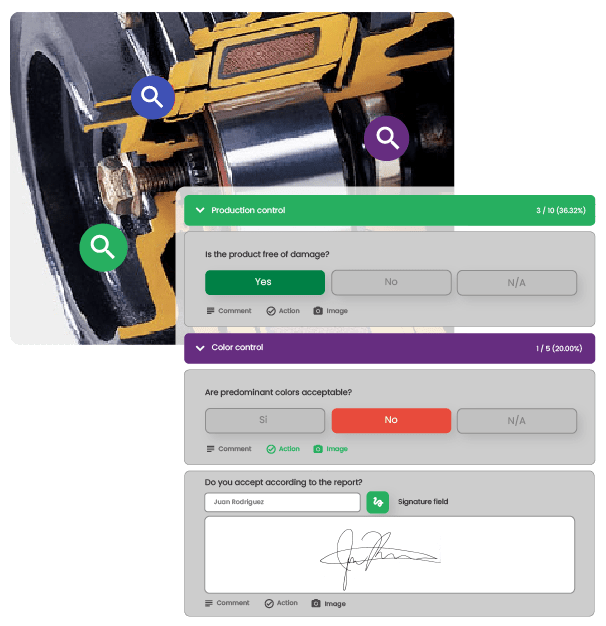

Quality control (QA)

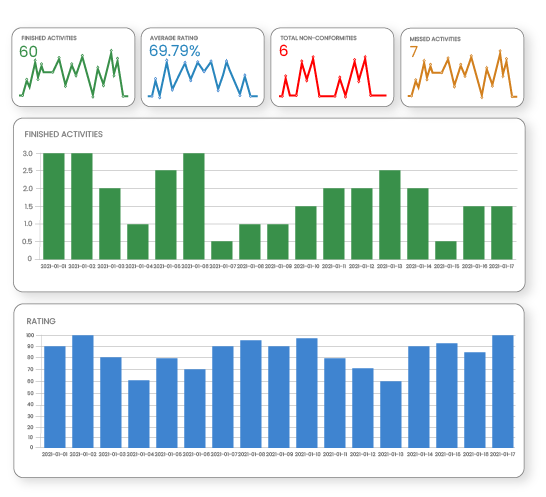

Increase quality and decrease lead time

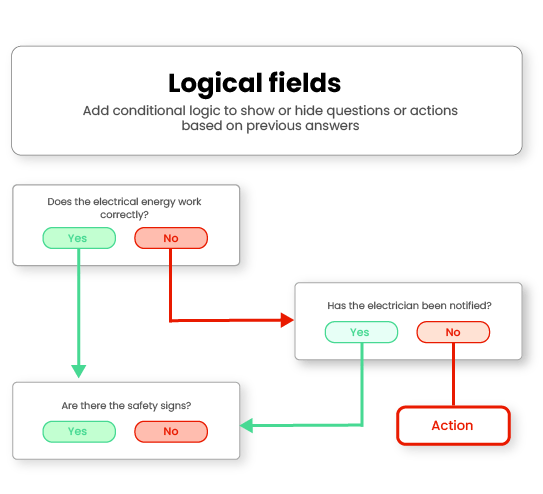

The implementation of quality control, through intelligent forms and the management of non-conformities, allow to reduce the use of materials and time as well as helping to prevent losses, improving the quality of the product or service.

Quality control (QA)

Increase quality and decrease lead time

The implementation of quality control, through intelligent forms and the management of non-conformities, allow to reduce the use of materials and time as well as helping to prevent losses, improving the quality of the product or service.

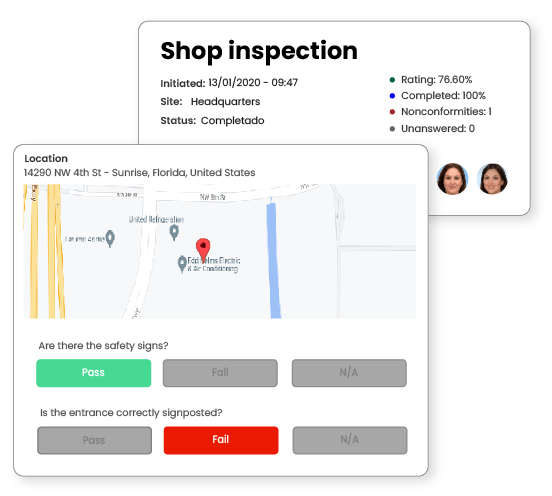

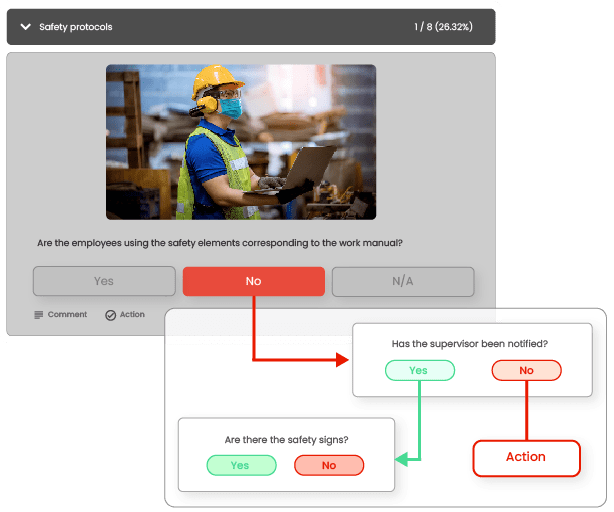

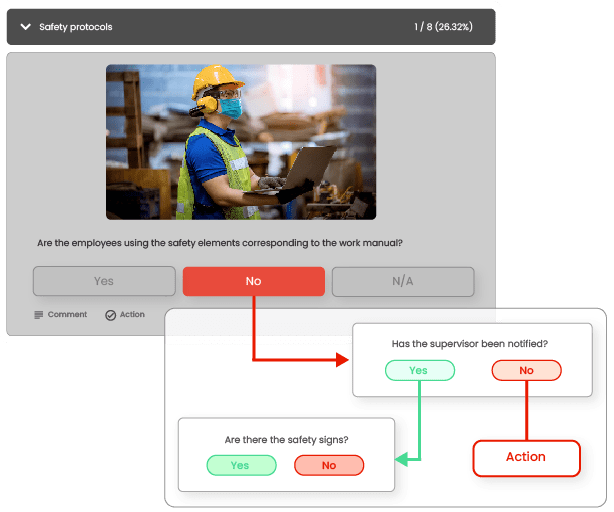

Safety protocols

Check your safety protocols

Configure smart forms in accordance with occupational safety standards, to prevent accidents as well as protect your employees by verifying safety devices and the use of personal protective equipment. (PPE/JSA)

Safety protocols

Check your safety protocols

Configure smart forms in accordance with occupational safety standards, to prevent accidents as well as protect your employees by verifying safety devices and the use of personal protective equipment. (PPE/JSA)

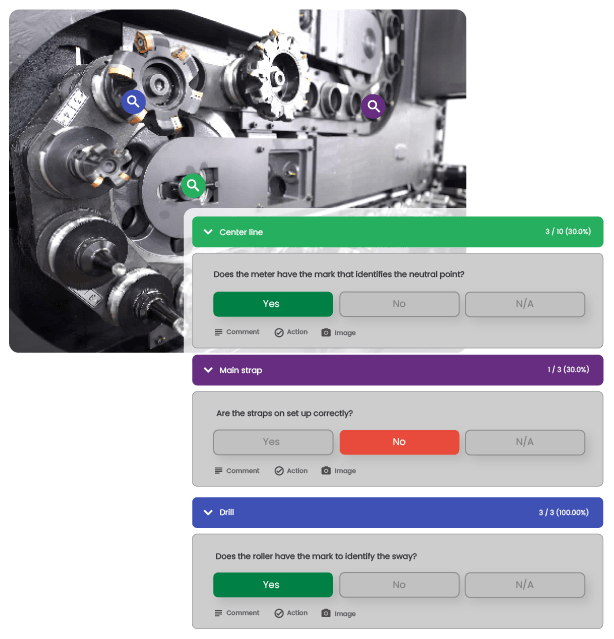

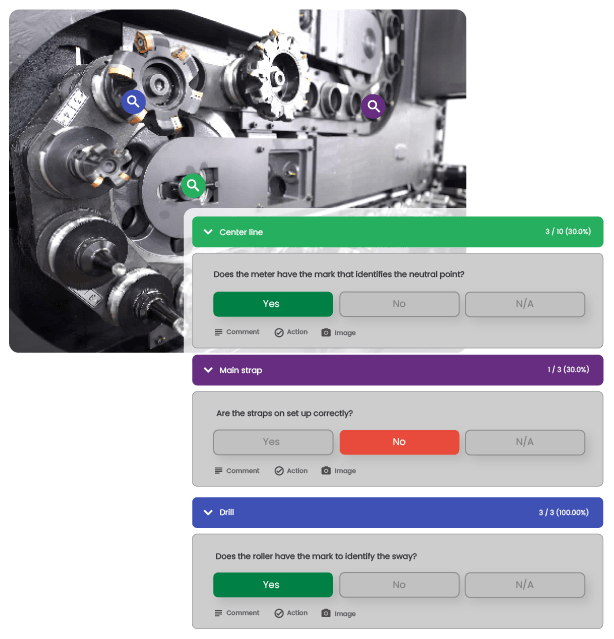

Maintenance inspections

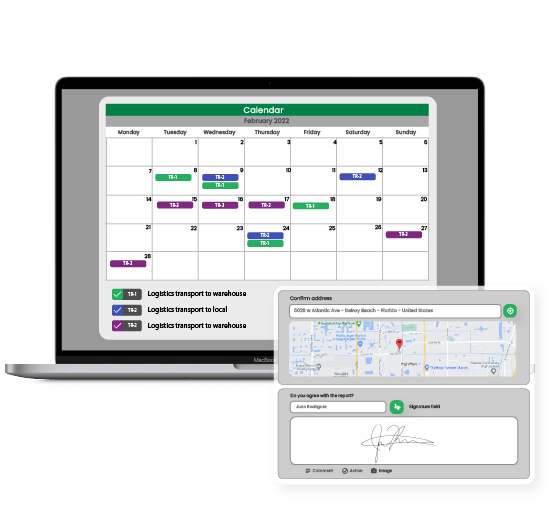

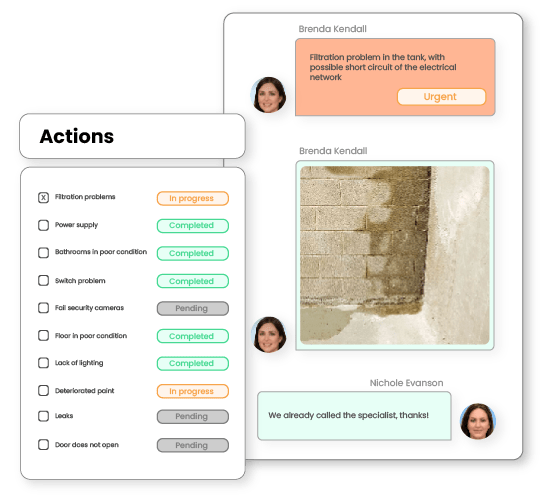

Reduce the downtime of your machinery to a minimum

Avoid damage and lost time in your equipment, performing regular maintenance inspections, whether corrective, predictive or preventive, considerably reducing your operating costs and improving your productivity.

Maintenance inspections

Reduce the downtime of your machinery to a minimum

Avoid damage and lost time in your equipment, performing regular maintenance inspections, whether corrective, predictive or preventive, considerably reducing your operating costs and improving your productivity.

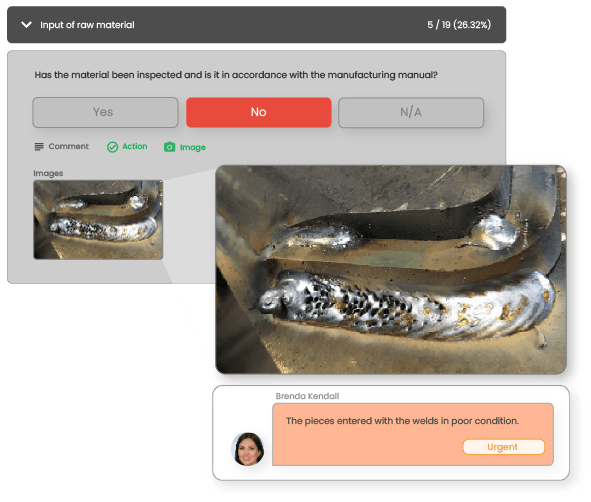

Supplier audit

Control quality from the start

Verify the raw material delivered by your suppliers from the beginning, thus ensuring the quality of your products and avoiding waste of time or unnecessary costs by entering raw material that does not conform to your production line.

Supplier audit

Control quality from the start

Verify the raw material delivered by your suppliers from the beginning, thus ensuring the quality of your products and avoiding waste of time or unnecessary costs by entering raw material that does not conform to your production line.

Uses and applications

Find here the solutions for your business problems

Quality control (QA)

Safety protocols

Maintenance inspections

Supplier audit

ISO 9001:2015 / 14001:2015 / 45001:2018

APPC (Dangers and critical points)

5S Audit

Cleaning control

Uses and applications

Find here the solutions for your business problems

Quality control (QA)

Safety protocols

Maintenance inspections

Supplier audit

ISO 9001:2015 / 14001:2015 / 45001:2018

APPC (Dangers and critical points)

5S Audit

Create your free account!

mail